1. Door panel

The total thickness of the door panel is 40mm ± 1mm, with a double-sided 0.5mm thick Baosteel color coated steel plate. The coating treatment from top to bottom includes a polyester coating, primer, passivation layer, and galvanized layer, with orange embossing and strip shaped reinforcement on both sides to enhance the strength of the door panel. The hard polyurethane foam material is filled between the two layers of steel plates, with a density of about 40kg/cubic meter and a thermal conductivity coefficient of less than 0.033W/m.k. A continuous steel strip is installed at the hinge installation position to ensure a secure installation of the hinge. Set an 80mm high reinforcing rib on the inner side of each door panel with a height of more than 5m to ensure that the door panel has a wind resistance strength of more than 12 levels. A EPDM rubber sealing strip is arranged at the bottom of the segmented door panel, and an air bag is arranged in the sealing strip. The heads on both sides of the door panel are δ= 1.0mm galvanized steel plate head piece.

2. Hardware accessories:

The door panel connection hinge is made of hot-dip galvanized cold-rolled steel plate by stamping. Material thickness δ= 2.0mm, with a galvanized thickness greater than 28 µ m. The guide rail is δ= 3-inch industrial door dedicated guide rail made of 2mm hot-dip galvanized steel plate by rolling; The cross-sectional shape of the guide rail is equipped with anti detachment hooks to ensure smooth operation of the guide wheel within the guide rail; The guide rail guard is δ= 2mm hot-dip galvanized steel plate is produced by rolling, and the protective plate is equipped with slots for sealing rubber on the door side and installation holes connected to the guide rail; Guide wheel mining Φ Special guide wheel for 72mm industrial doors, made of wear-resistant nylon with roller bearings, ensuring smooth operation and no noise. All other hardware accessories are made of hot-dip galvanized steel sheet stamping, with accurate dimensions and good interchangeability.

3. Balancing system:

The sliding door adopts torsion spring balance, and the balance torsion spring is designed and manufactured based on the calculation of the door's heavy load software to achieve the best balance. The torsion spring material is made of imported 60si2Mn spring steel, ensuring a service life of over 80000 cycles. The balance shaft of the sliding door is Ф 25.4 solid round steel, equipped with a torsion spring fracture protection device on the balance shaft, which can prevent the door panel from falling when the balance torsion spring breaks; The lifting rope pulley is an aluminum cylindrical rope pulley.

The Factor of safety of the lifting wire rope is more than 5 times of the door weight, and the door plate is equipped with anti wire rope fracture devices to ensure the safe operation of the door plate.

4. Safety protection device:

① There is a safety airbag at the bottom of the door, which can automatically reverse to the fully open state when encountering obstacles during the closing process of the door;

② A blade type steel wire rope fracture protector is installed at the bottom two ends of the door. When the lifting steel wire rope breaks and the door body moves faster, this device can cut into the guide rail to prevent the door body from falling;

③ The motor is equipped with a release and clutch device, which can manually operate the door movement when switching to manual mode.

5. Sealing strip:

EPDM rubber sealing strips are set at the top and both sides of the door opening, and EPDM rubber air bags and sealing wings are set at the bottom of the door body to ensure good tightness between the door body and the building.

6. Industrial sliding operation:

Liftgate operation is divided into manual control mode and electric control mode:

1) Manual control method: The door can be lifted and lowered manually in one go. In the event of a power outage, the door can be manually opened.

2) Electric control method: On the basis of manual control, there is a standard operating button box next to (on the inside) each lifting door, which can be opened and closed by manipulating the up, stop, and down buttons on the button box. And when the door body reaches the set position, it automatically stops.

3) Manual/automatic switching: There is a clutch release device installed on the motor. When there is a power outage, the clutch release device can be manually operated to switch the driver from electric to manual, and the door can be opened and closed manually.

Product Features

Curtain material: Made of double-layer high-strength, high toughness, and corrosion-resistant aluminum alloy extruded into shape.

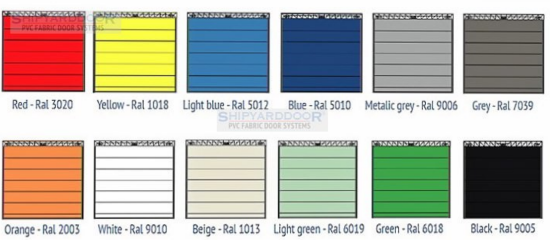

Surface treatment: classic powder spraying process, which is characterized by strong durability, anti-aging, corrosion resistance, fade resistance, easy maintenance, and lasting as new.

Scope of application: Suitable for exterior doors of medium to high-end factories.

Opening speed: The average speed can reach 12-18 meters per minute;

Operating principle: The door pieces with multiple joint movements are connected in series and fixed in the guide rail slide, rotating up and down centered on the scroll above the door.

Driving principle: Use a dedicated motor to drive the central axis of the roller shutter to rotate, reaching the roller shutter switch. When it reaches the upper and lower limits set by the motor, it automatically stops.

Appearance: The inner and outer surfaces of the door body have been specially treated to meet the appearance requirements of various modern industrial factories.

Wind resistance: By strengthening the interior of the door panel and cooperating with other strengthening accessories, the Marai industrial door can withstand the requirements of strong winds of level 12.

Transparency: Double layer insulated glass with rectangular or elliptical design, surrounded by a flexible rubber perspective window on the outside, providing good daylighting and transparency.

Anti theft: Provide dedicated door latches and locks that can be locked from the inside, combined with a sturdy door body, effectively preventing tampering and theft.